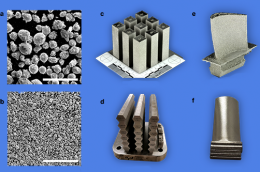

In recent years, it has become possible to use laser beams and electron beams to “print” engineering objects with complex shapes that could not be achieved by conventional manufacturing. The additive manufacturing (AM) process, or 3D printing, for metallic materials involves melting and fusing fine-scale powder particles — each about 10 times finer than a grain of beach sand — in sub-millimeter-scale “pools” created by focusing a laser or electron beam on the material.

“The highly focused beams provide exquisite control, enabling ‘tuning’ of properties in critical locations of the printed object,” said Tresa Pollock, a professor of materials and associate dean of the College of Engineering at UC Santa Barbara. “Unfortunately, many advanced metallic alloys used in extreme heat-intensive and chemically corrosive environments encountered in energy, space and nuclear applications are not compatible with the AM process.”

The challenge of discovering new AM-compatible materials was irresistible for Pollock, a world-renowned scientist who conducts research on advanced metallic materials and coatings. “This was interesting,” she said, “because a suite of highly compatible alloys could transform the production of metallic materials having high economic value — i.e. materials that are expensive because their constituents are relatively rare within the earth’s crust — by enabling the manufacture of geometrically complex designs with minimal material waste.

“Most very-high-strength alloys that function in extreme environments cannot be printed, because they crack,” continued Pollock, the ALCOA Distinguished Professor of Materials. “They can crack in their liquid state, when an object is still being printed, or in the solid state, after the material is taken out and given some thermal treatments. This has prevented people from employing alloys that we use currently in applications such as aircraft engines to print new designs that could, for example, drastically increase performance or energy efficiency.”

Now, in an article in the journal Nature Communications, Pollock, in collaboration with Carpenter Technologies, Oak Ridge National Laboratory, UCSB staff scientists Chris Torbet and Gareth Seward, and UCSB Ph.D. students Sean Murray, Kira Pusch, and Andrew Polonsky, describes a new class of superalloys that overcome this cracking problem and, therefore, hold tremendous promise for advancing the use of AM to produce complex one-off components for use in high-stress, high-performance environments.

The research was supported by a $3 million Vannevar Bush Faculty Fellowship (VBFF) that Pollock was awarded from the U.S. Department of Defense in 2017. The VBFF is the Department of Defense’s most prestigious single-investigator award, supporting basic research that could have a transformative impact.

In the paper, the authors describe a new class of high-strength, defect-resistant, 3D-printable superalloys, defined as typically nickel-based alloys that maintain their material integrity at temperatures up to 90% of their melting point. Most alloys fall apart at 50% of their melting temperatures. These new superalloys contain approximately equal parts cobalt (Co) and nickel (Ni), plus smaller amounts of other elements. These materials are amenable to crack-free 3D printing via electron beam melting (EBM) as well as the more challenging laser-powder-bed approaches, making them broadly useful for the plethora of printing machines that are entering the market.

Because of their excellent mechanical properties at elevated temperatures, nickel-based superalloys are the material of choice for structural components such as single-crystal (SX) turbine blades and vanes used in the hot sections of aircraft engines. In one variation of a superalloy that the team developed, Pollock said, “The high percentage of cobalt allowed us to design features into the liquid and solid states of the alloy that make it compatible with a wide range of printing conditions.”

The development of the new alloy was facilitated by previous work done as part of NSF-funded projects aligned with the national Materials Genome Initiative, which has the underlying goal of supporting research to address grand challenges confronting society by developing advanced materials “twice as fast at half the cost.”

Pollock’s NSF work in this area was conducted in collaboration with fellow UCSB materials professors Carlos G. Levi and Anton Van der Ven. Their efforts involved developing and integrating a suite of computational and high-throughput alloy design tools needed to explore the large multicomponent composition space required to discover new alloys. In discussing the new paper, Pollock also acknowledged the important role of the collaborative research environment in the College of Engineering that made this work possible.

Contact Info:

James Badham

jwbadham@ucsb.edu